Robotics Lab – Engineering Intelligent Machines

A hands-on learning space for designing, building, and programming intelligent robotic systems.

About Robotics and Automation Lab

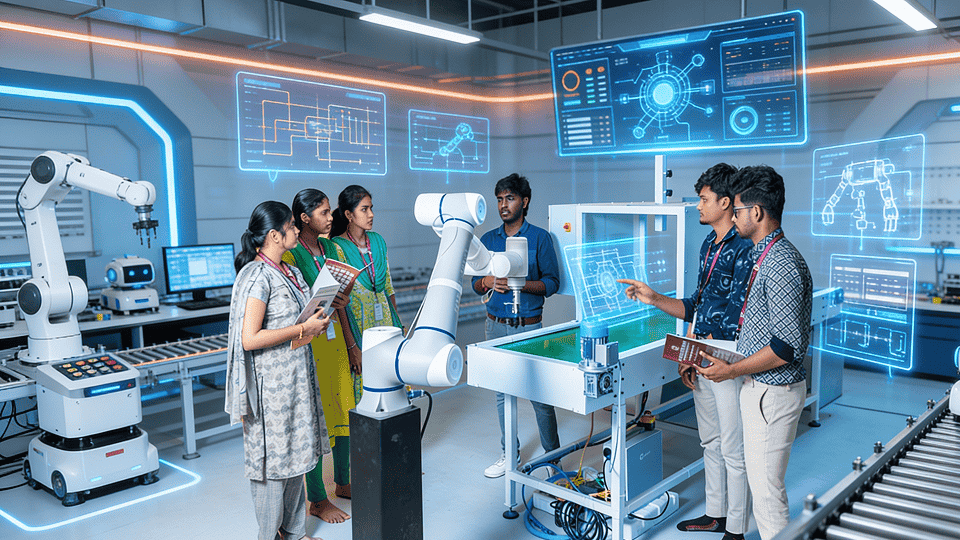

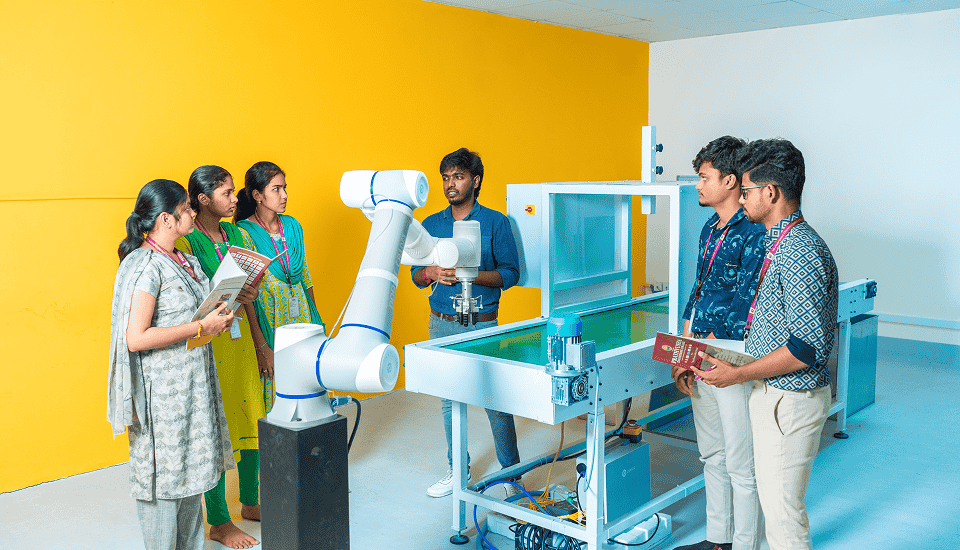

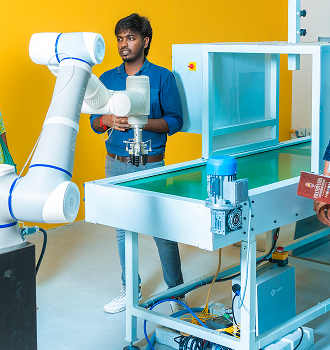

The Robotics and Automation Lab at Prathyusha Engineering College provides students with hands-on exposure to the design and development of intelligent robotic and automated systems.

The lab focuses on integrating mechanics, electronics, and programming to create real-world solutions for industrial automation, smart manufacturing, healthcare, and service robotics. Equipped with modern tools such as Cobot, sensors, actuators, microcontrollers, PLCs, and robotic platforms, the lab helps students build practical skills aligned with current industry needs.

What Students Experience

Robotics & Automation Labs

Hands-on training with robots, PLCs, sensors, and controllers

Industrial Automation

Real-world automation systems used in modern industries

Autonomous Robots

Design and develop intelligent, self-operating machines

Smart Manufacturing

Exposure to Industry 4.0 and IoT-enabled systems

Safety & Control Systems

Learn safe and efficient industrial operations

Transforming Learning through Intelligent Automation

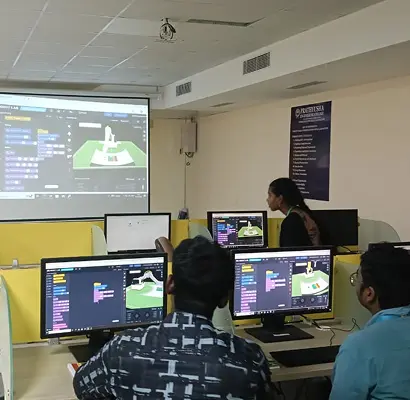

Robotics Labs & Simulations

Students gain practical learning through robotics simulations and hands-on labs that replicate real-world automation scenarios. These experiences strengthen understanding of robotic kinematics, control systems, and automation workflows.

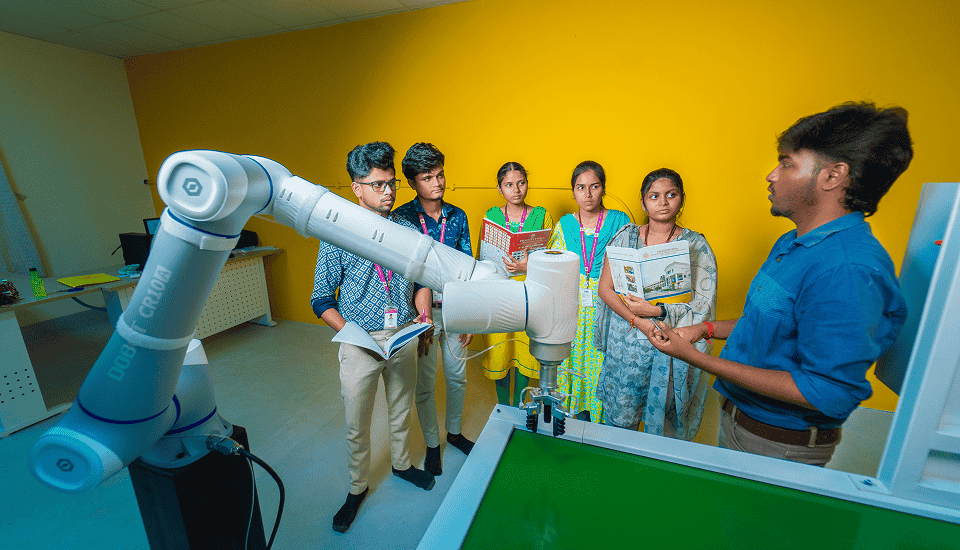

Industrial Automation Training

The lab enables students to work with PLCs, sensors, actuators, and control panels used in modern industries. Learners design and test automated systems for manufacturing and process control applications.

Autonomous Robot Development

Students design and build mobile and autonomous robots using microcontrollers, embedded systems, and AI-based decision-making. This enhances skills in navigation, sensing, and real-time control.

Smart Manufacturing Systems

Hands-on projects focus on smart factories, conveyor systems, robotic arms, and IoT-enabled automation. These setups prepare students for Industry 4.0 environments and intelligent production systems.

Safety & Control Systems

Automation-based safety systems are explored through emergency controls, fault detection, and monitoring solutions. This helps students understand safe operation and risk mitigation in industrial settings.

Workshops & Hands-On Training

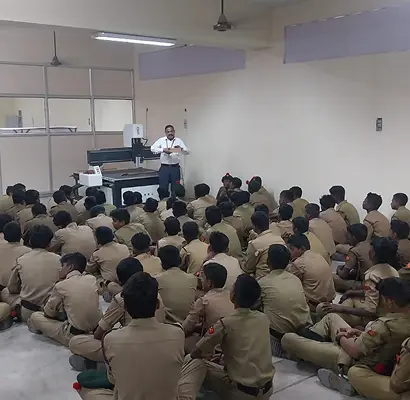

Robotics & Automation Boot camps

Intensive hands-on programs introduce students to robot programming, PLC automation, sensor integration, and system troubleshooting through real-world use cases.

Industry Expert Sessions

Interactive sessions led by robotics and automation professionals provide insights into industrial practices, emerging technologies, and career pathways in automation engineering.

Robotics Hackathons & Challenges

Team-based events where students design and build robotic or automated solutions within a limited time, encouraging innovation, collaboration, and problem-solving skills.

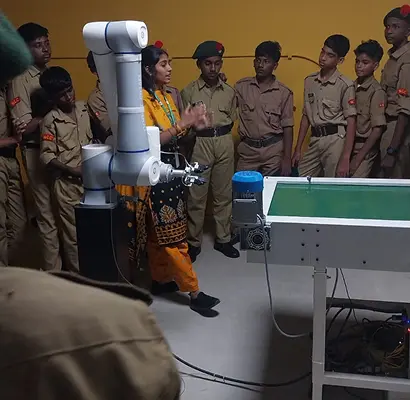

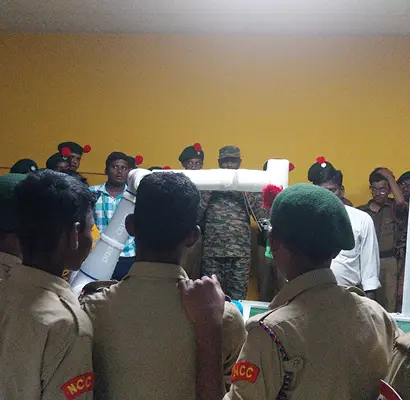

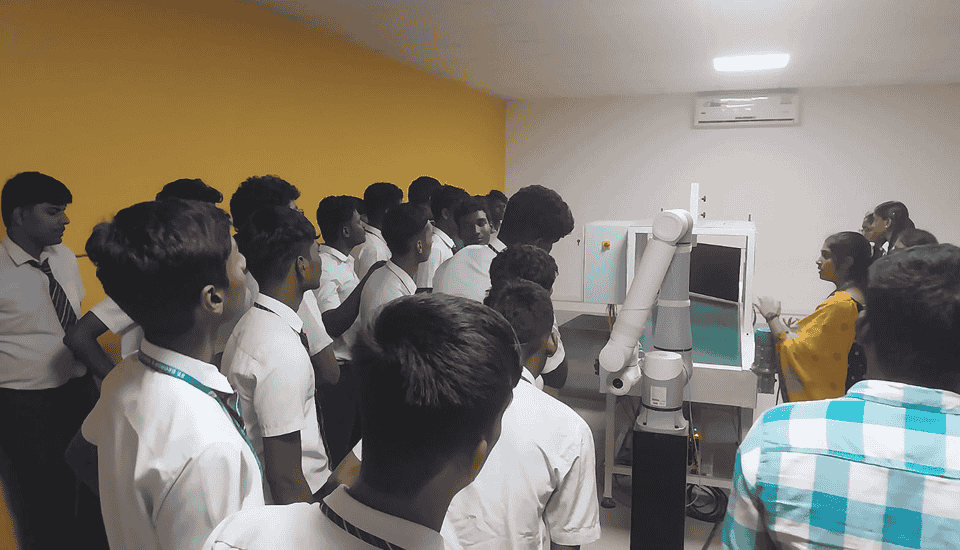

Robotics & Automation Events

The Robotics and Automation Lab hosts technical events, live demonstrations, project expos, and competitions that showcase student innovations and emerging trends in robotics and industrial automation. These events promote experiential learning, interdisciplinary collaboration, and strong industry engagement.